THOR

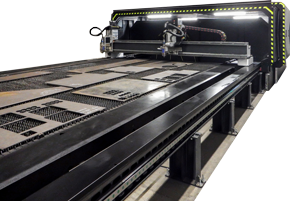

TECOI’s THOR guarantees tailor-made solutions for each customer’s needs. In addition to its flexibility of operation, it has the advantage of combining thermal cutting with high-performance machining. The XX central axis has a useful stroke of 610 mm.

versatility

TECOI’s THOR is the most versatile plate processing station on the market, allowing the production of parts with multiple operations such as milling, drilling, tapping, countersinking, marking, etc.

Technologies

- Multi-head: it can be equiped with one or two plasma heads and bevelling system.

- Oxyfuel up to six torches

- Optionally, a tube and profile lathe with fixed gantry can be added

- Possibility of installing two machining heads

Highest productivity

Its design, sturdiness and extra reinforced guides have been developed for heavy-duty applications and maximum productivity

Adaptability

The wide range of equipment options ensures that each machine can be customised to meet the customer’s production needs.

THOR

TECOI’s THOR guarantees tailor-made solutions for each customer’s needs. In addition to its flexibility of operation, it has the advantage of combining thermal cutting with high-performance machining. The XX central axis has a useful stroke of 610 mm.

versatility

TECOI’s THOR is the most versatile plate processing station on the market, allowing the production of parts with multiple operations such as milling, drilling, tapping, countersinking, marking, etc.

Technologies

- Multi-head: it can be equiped with one or two plasma heads and bevelling system.

- Oxyfuel up to six torches

- Optionally, a tube and profile lathe with fixed gantry can be added

- Possibility of installing two machining heads

Highest productivity

Its design, sturdiness and extra reinforced guides have been developed for heavy-duty applications and maximum productivity

Adaptability

The wide range of equipment options ensures that each machine can be customised to meet the customer’s production needs.

Tels.: (+34) 987 702 047

Fax: (+34) 987 703 131

Email: info@tecoi.com

Polígono Industrial “La Herrera I”, Sahelices de Sabero, 24812 (León), España

![experiencia2ok[EN]](https://tecoi.com/wp-content/uploads/2021/05/experiencia2okEN.jpg)

![TEKNOS[menu]](https://tecoi.com/wp-content/uploads/2021/05/TEKNOSmenu.png)

![TRC[menu]](https://tecoi.com/wp-content/uploads/2021/05/TRCmenu.png)

![THOR[menu]](https://tecoi.com/wp-content/uploads/2021/05/THORmenu.png)

![FL[plasma]](https://tecoi.com/wp-content/uploads/2021/05/FLplasma.png)

![mb[new]](https://tecoi.com/wp-content/uploads/2022/12/mbnew.png)

![trf[menu]](https://tecoi.com/wp-content/uploads/2021/05/trfmenu.png)

![tornos-elevadores[en]](https://tecoi.com/wp-content/uploads/2021/05/tornos-elevadoresen.png)

![FILTROS[en]](https://tecoi.com/wp-content/uploads/2021/05/FILTROSen.png)

![bancos[en]](https://tecoi.com/wp-content/uploads/2021/05/bancosen.png)